- Homehome

- Productproduct

- Pyrolysis System for Lithium Battery Industry Waste

- Physical Recycling (Milling) Equipment for Battery Electrode Slice

- Equipment for harmless treatment and resource recovery of Waste Refrigerators

- Integrated equipment for crushing, sorting and scrap steel processing of scrappe

- Equipment for pretreatment and fine disassembly of end-of-life vehicles

- Waste tire crushing, sorting and pretreatment equipment

- Crushing single machine series equipment

- Large waste crushing and sorting equipment

- Solutionscheme

- Urban and rural waste resource utilization ecological industrial chain

- Classified collection and transportation reverse logistics network and big data information internet

- Recycling of urban recyclables (blue island)

- Rural waste collaborative disposal (Green Island)

- Distributed RDF and intensive energy conversion (energy island)

Know More

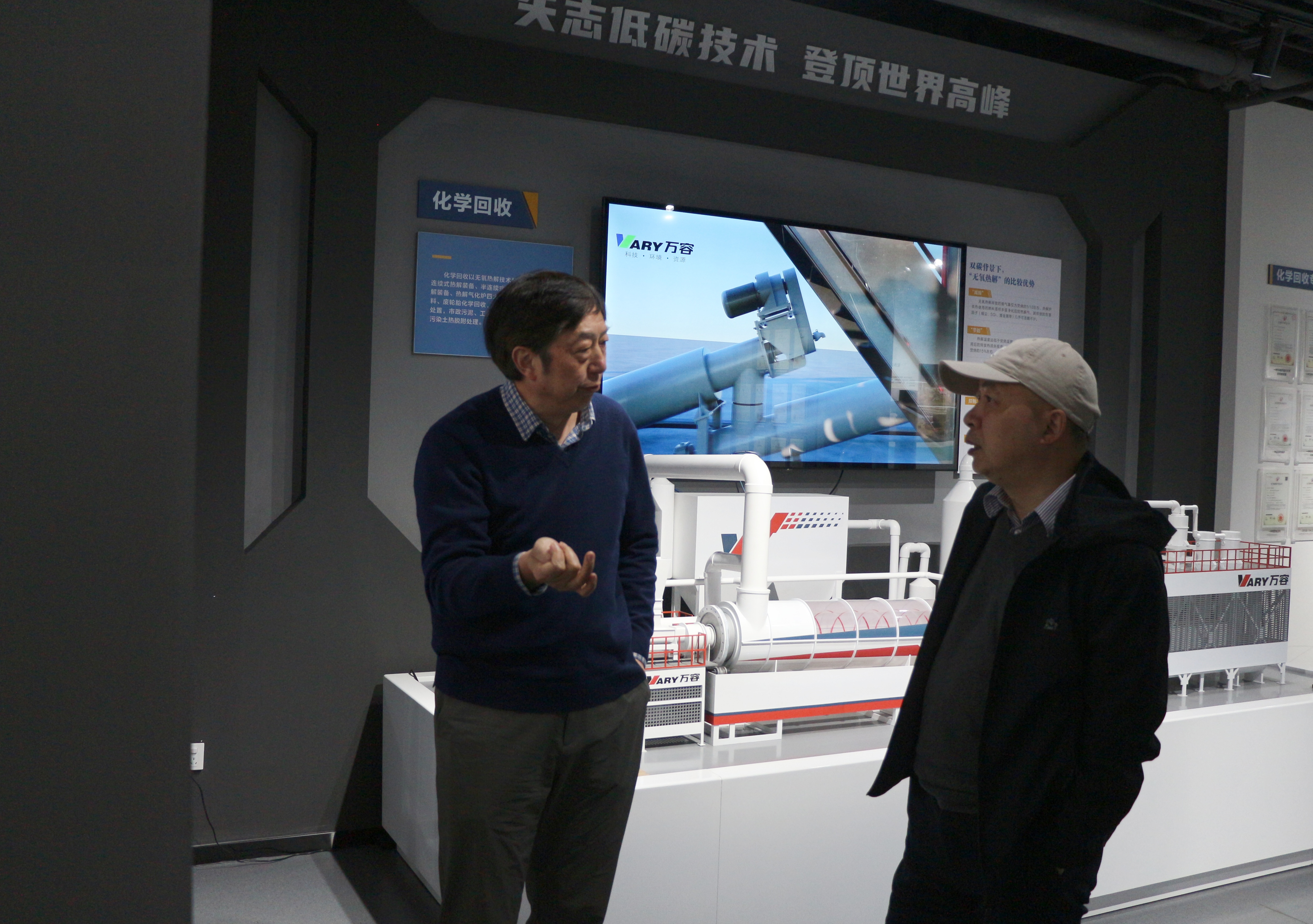

Know MoreIn the face of global warming, energy crisis and China’s "carbon peaking and carbon neutrality" goal, Vary Tech has always adhered to the original intention of "resource utilization", actively deployed the biochar industry, and is committed to becoming a high-quality service provider of global biomass carbon materials, providing professional system equipment and high-quality biomass carbon products.

Know More

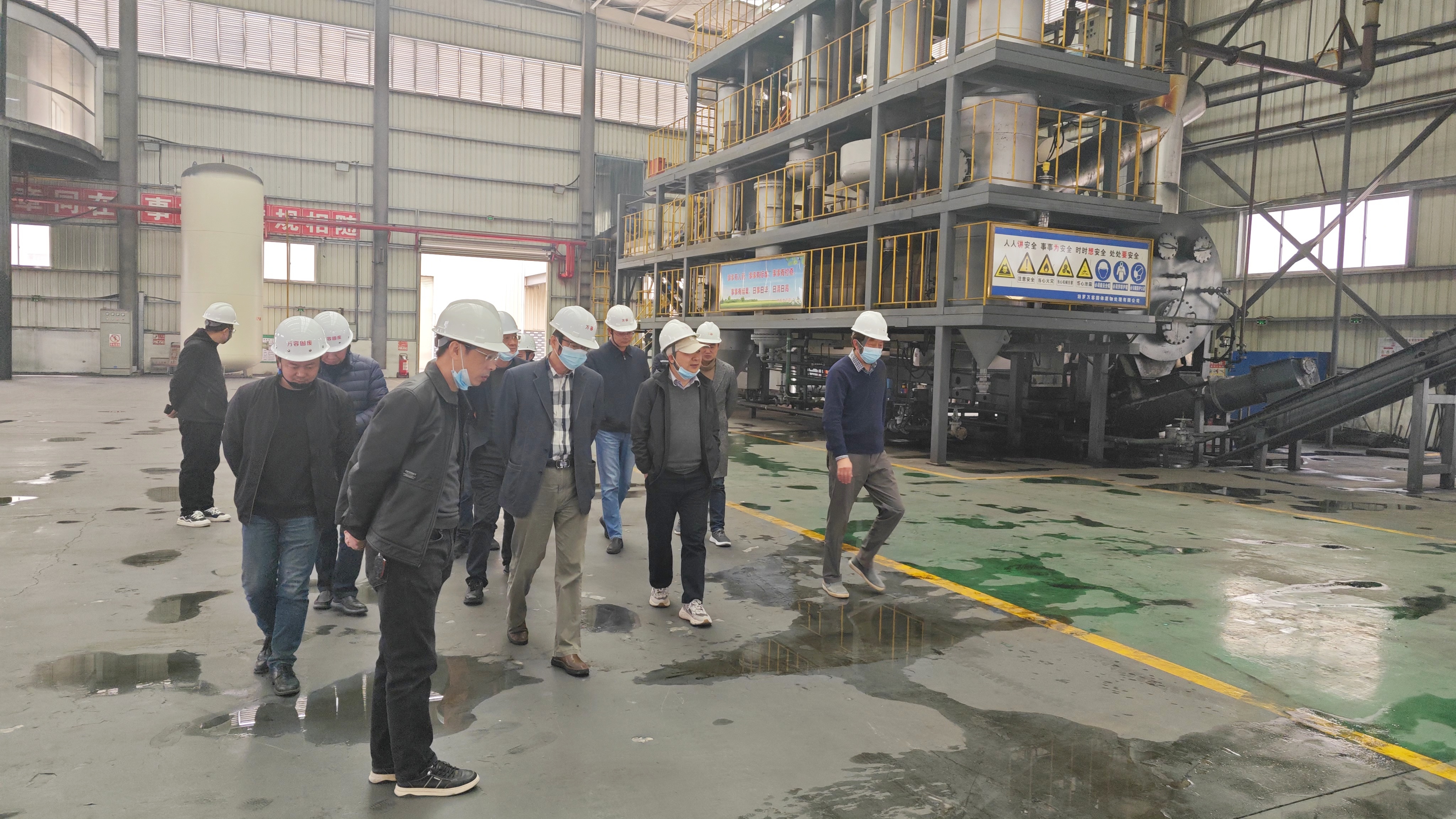

Know MoreThe technology and equipment for harmless treatment and resource recovery of Waste Refrigerators independently developed by the company has a unique patent combination design of "double shaft shredder + vertical crusher + large air volume dilution cyclopentane gas". It is mainly used for the separation, recovery and utilization of various raw materials in waste refrigerators. It has independent intellectual property rights, The scientific and technological achievements of the Ministry of industry and information technology were identified as "filling the domestic gap and reaching the international advanced level".

Know More

Know MoreAdopt anaerobic pyrolysis technology to realize the physical and chemical recovery of waste tires and plastics, and solve the "white pollution" and "black pollution" that perplex the world. Provide crushing and sorting equipment, front-end pretreatment and terminal pyrolysis, and whole plant system services for comprehensive utilization of waste tires. On the premise of safe, environmental protection, continuous and stable operation, waste tires (waste rubber products) are finally transformed into steel wire, pyrolysis oil and pyrolysis carbon to realize resource-based, harmless and reduction disposal. Packaging waste plastics, sorted municipal waste, industrial waste plastics, agricultural film, paper mill waste, etc. can no longer be used directly. After crushing, sorting and anaerobic pyrolysis, they are finally transformed into high calorific value energy products, pyrolysis oil and pyrolysis carbon, so as to realize resource-based, harmless and reduction disposal.

Know More

Know MoreProvide pyrolysis resource utilization system services for waste packaging containers / materials and medical wastes. Hazardous waste packaging containers finally form iron, pyrolytic oil and pyrolytic carbon through "decapping and flattening + pyrolysis + crushing and screening" and "crushing + pyrolysis + screening", so as to achieve the effect of resource utilization of hazardous waste packaging. The medical waste is poured into the feed bin by the movable Tipper and then fed into the pyrolysis and carbonization treatment by the double roller feeder. The product pyrolysis oil and pyrolysis carbon can be sold as fuel.

Know More

Know MoreIt is applicable to municipal sludge produced by urban sewage treatment plants, underground pipe networks and river channels, and industrial sludge produced by paper making, printing and dyeing, leather industry and down manufacturing industry; Oily contaminated waste, ground sludge, refinery sludge, tank bottom sludge, drilling cuttings, ground oil spill and other oily sludge (hw08). After pretreatment, sludge and oil sludge are finally transformed into main products such as pyrolysis oil and pyrolysis carbon through anaerobic pyrolysis technology and equipment on the premise of safe, environmental protection and stable operation, so as to realize their reduction, harmless treatment and resource utilization.

- Casecases

Know More

The company is rooted in the field of urban and rural waste resource utilization, and its business covers many regions at home and abroad. It has mature cases in the field of resource utilization such as electronic waste, scrap cars and scrap steel, domestic waste, recyclables, perishable waste, solid and hazardous waste, oily sludge, industrial sludge, waste tires and waste rubber.

- Newsnews

Know More

Vary will firmly take protecting the earth's home as its own responsibility, create a sustainable development road of "turning garbage into resources" with the natural ecosystem model advocated by "blue economy", and strive to build a world leading resource and environmental service enterprise.

- Aboutabout

Know More

Vary Technology Co., Ltd. is committed to building a world leading resource and environmental management service enterprise. We provide core equipment products and system solutions for the three markets of "industrial solid waste and hazardous waste disposal", "classified disposal of urban waste" and "coordinated disposal of urban and rural waste".

- Contactcontact